Innovating Manufacturing

Sites by Applying AI

Our Services

Three functions to solve “on-site issues” from customers.

Cutting Edge

Technology

Utilize innovative technology to build AI models (deep learning/big data analysis).

Realization of

Predictive Maintenance

Predictive detection avoids the risk of emergency maintenance due to sudden breakdowns.

Automated Detection

and Inspection

Automate tasks that used to rely on manual labor.

Numerous Knowledge

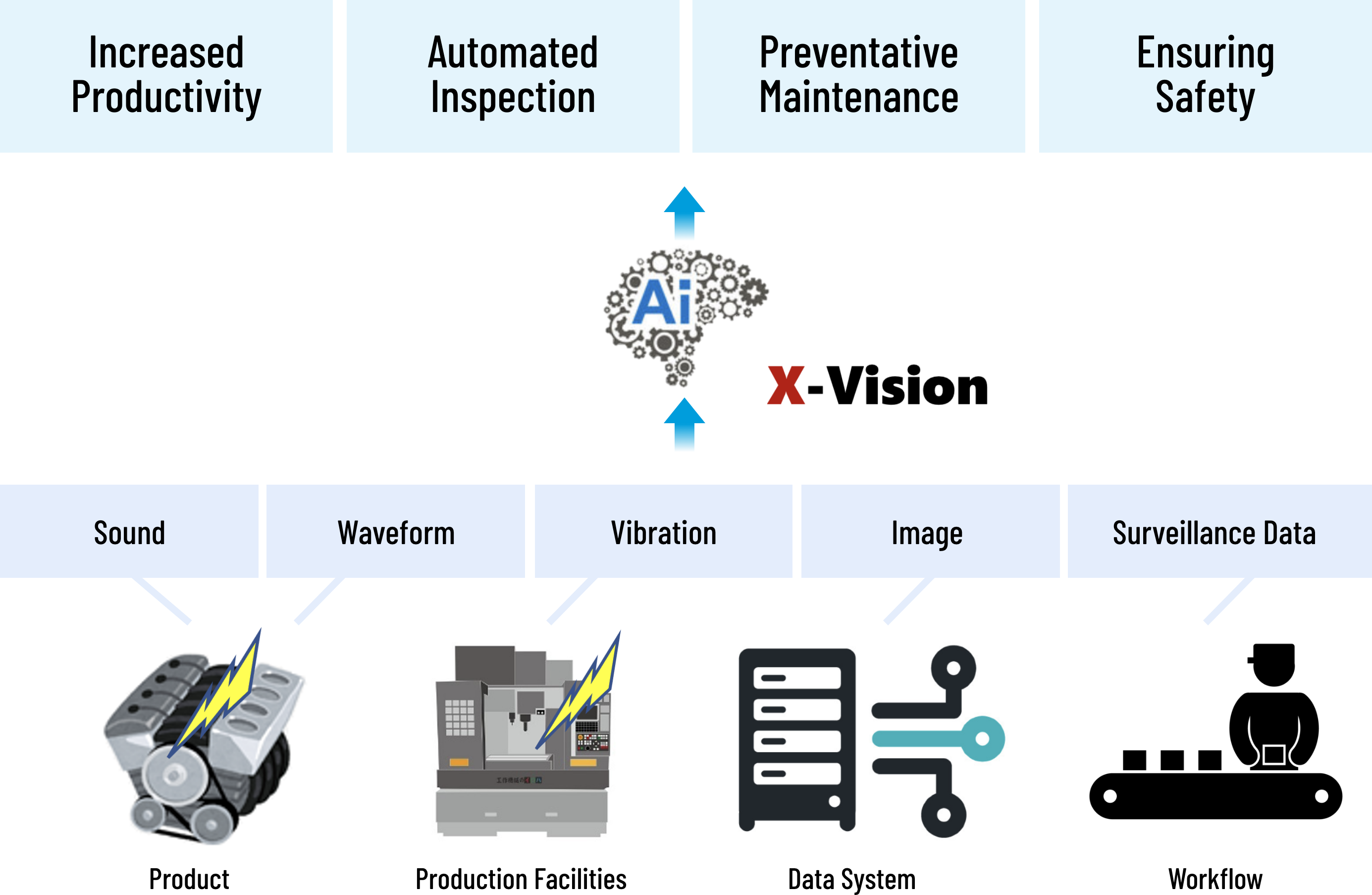

Image pattern classification and flaw detection. Flaw detection using sound and vibration data. Area detection, human motion analysis, etc.

Additional

On-site Learning

Provided methods that enables customers to learn more.

Our Advantage

Modern AI technologies bringing innovation to manufacturing facilities. The implementation of X-Vision will significantly increase on-site productivity, automate inspections, perform predictive maintenance, and ensure safety.

Example

CASE01

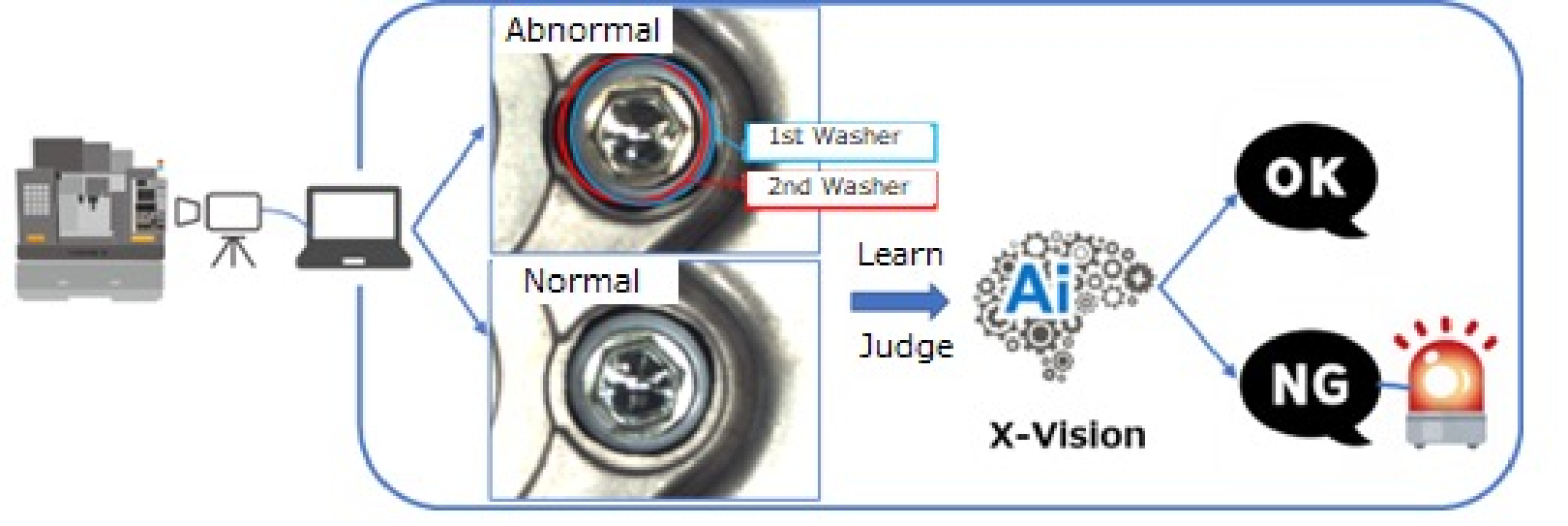

Detecting Component Assembly Errors by Image Recognition

| Flaw Assembly Detection Misjudgment Rate |

Similer Parts Clasification Misjudgment Rate |

|

|---|---|---|

| X-Vision | 0.003%(1/3060) | 1.6%(50/3060) |

| Other | 1.6%(50/3060) | 3.3%(12/360) |

Accuracy of judgment benchmark

Modern deep learning technology is used to further fine-tune the learning engine to achieve high accuracy.

CASE02

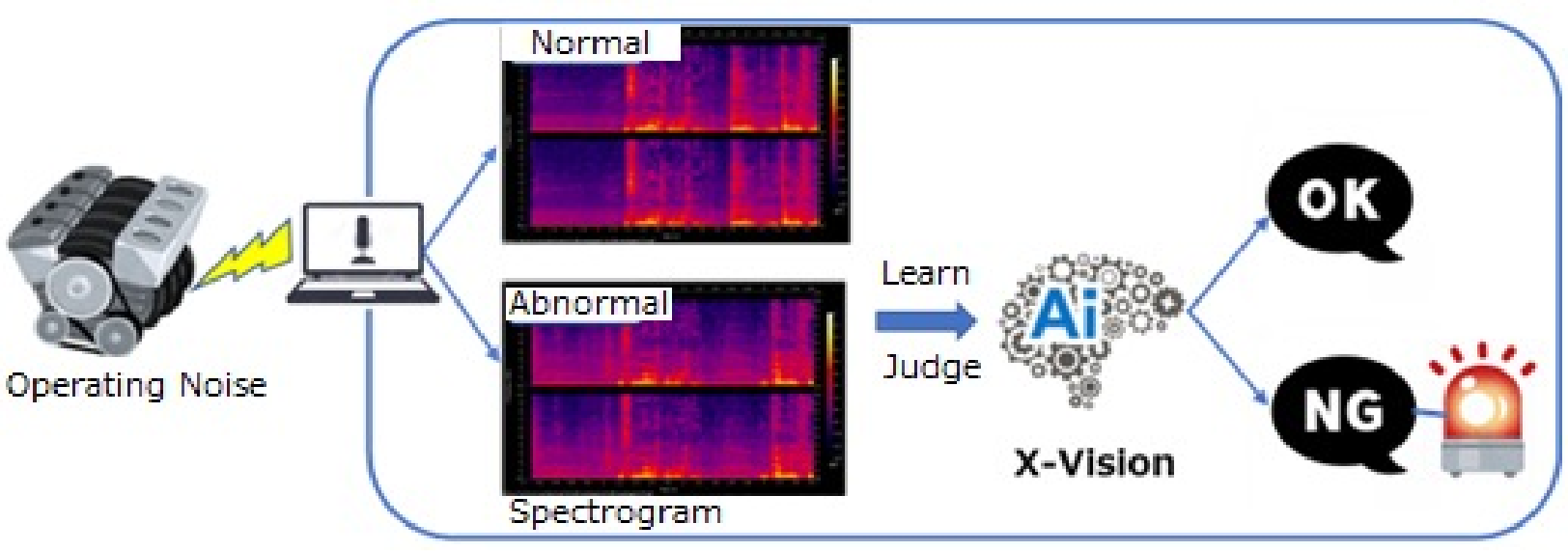

Automation of the Inspection Process Through Sound Visualization

By learning “visualized operating noise” and “inspection results of skilled inspectors on operating noise” with AI, sensory inspections can be automated.

Flow of Installation

-

Consulting

Assessment・Field Survey

・Problem Analysis

・Data Confirmation Proof of

Concept・Evaluate

・Decide to build a device

・Spec ReviewDevelopment

・AI model development

・Equipment developmentOperation

・Installation

・On-site operation

・Additional learning

・Follow-up services