Production History Management

in the Age of Big Data

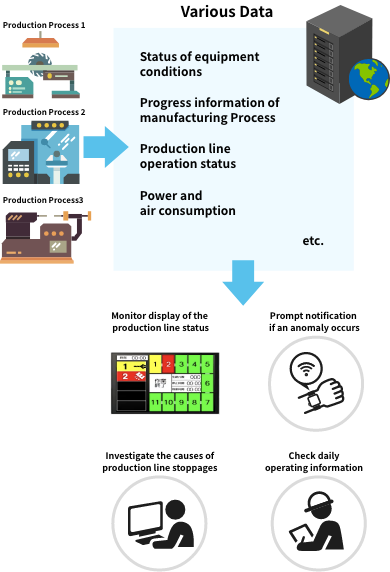

We “scollect” and “unify” various information obtained from manufacturing parts and production equipment, analyze the cause of defects from the accumulated information, and prevent the outflow of defective products.

Traceability Product Line

Our Advantage

We have experience and knowledge in delivering traceability systems to many factories. In addition to data collection, it also has a graph generation function for production trend analysis and a defective product judgment function.

Services Offered

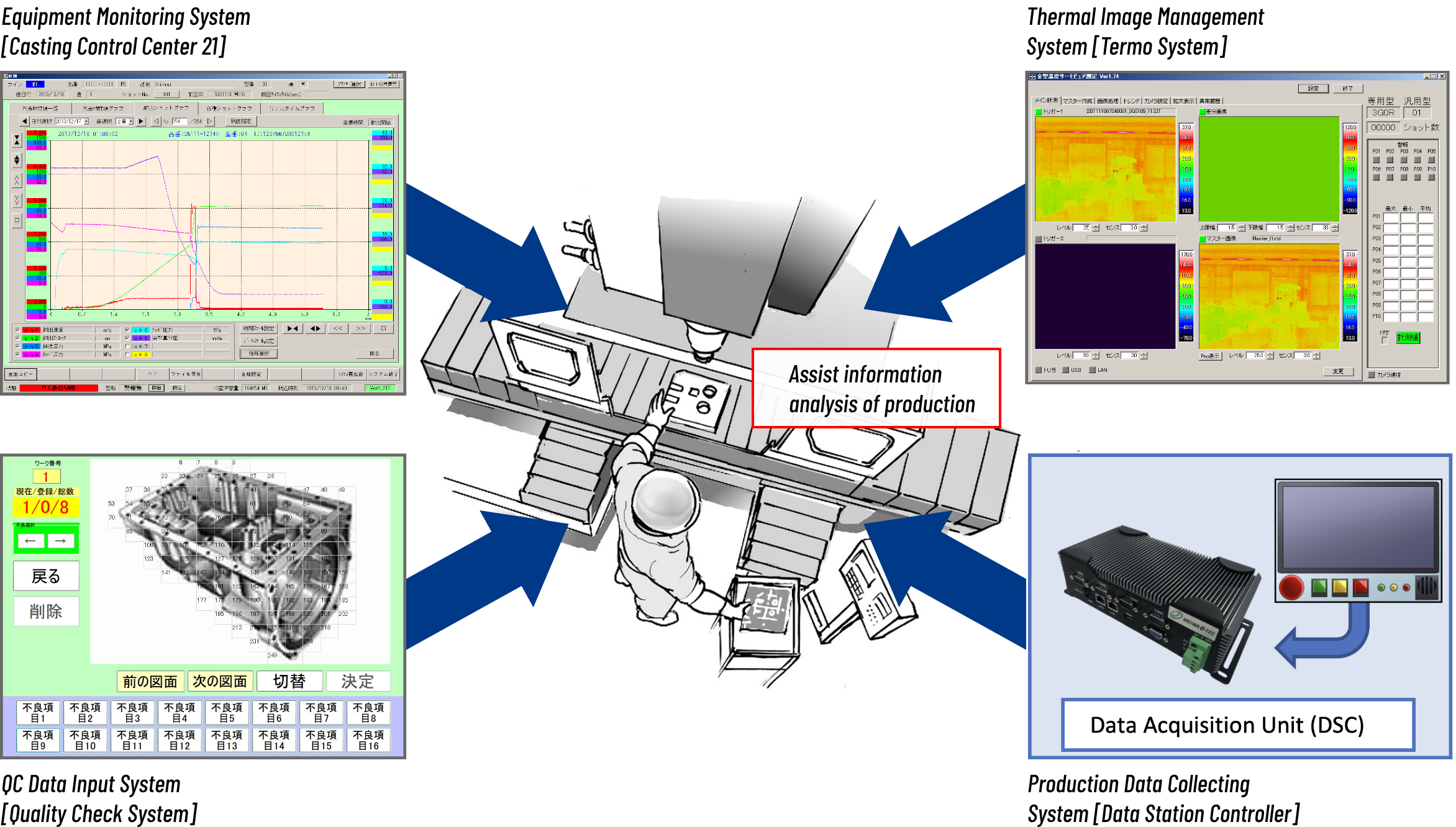

Five features that make the most of your facility information.

Centralized Management of

Various Information

We have a wide range of products that collect various information obtained from production equipment. By combining the functions of each product according to the application, you can build a traceability system and easily analyze the production status and the cause of defects.

A Wide Range of Facilities

We can propose a wide range of data collection methods, such as those using mold temperature measurement cameras and sensors during the casting process, and handwritten information for visual inspection.

Paperless

With paper records, it is difficult to track the history when defective products occur, but digitalization makes tracking easier.

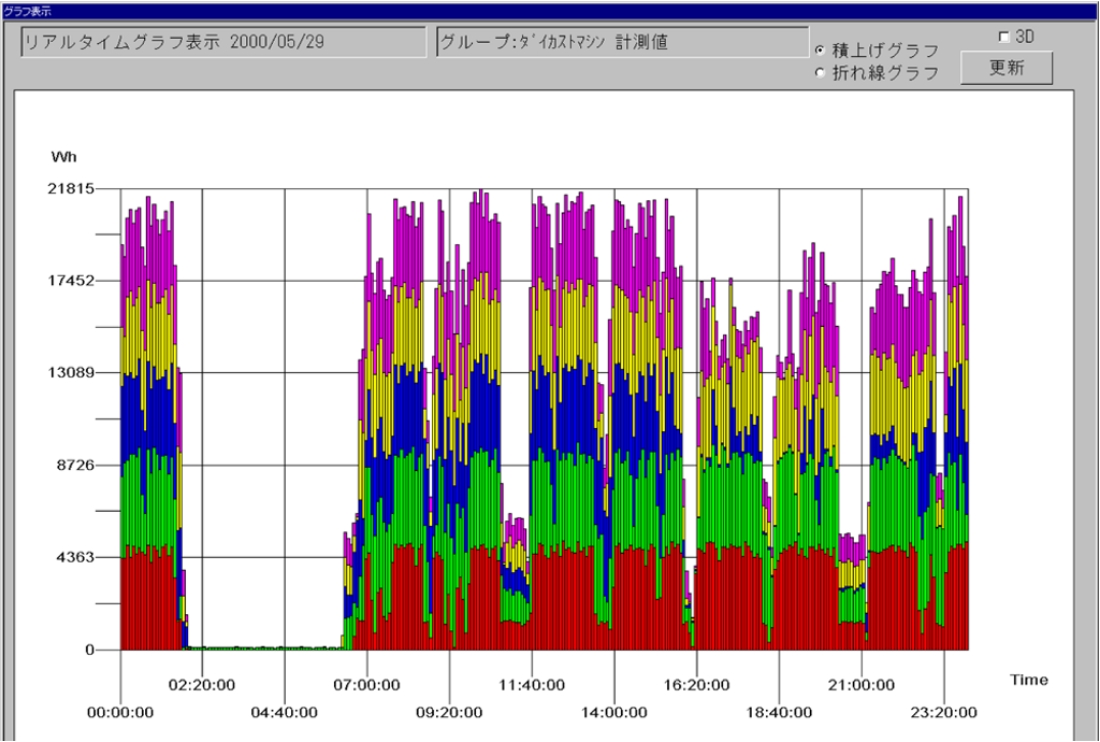

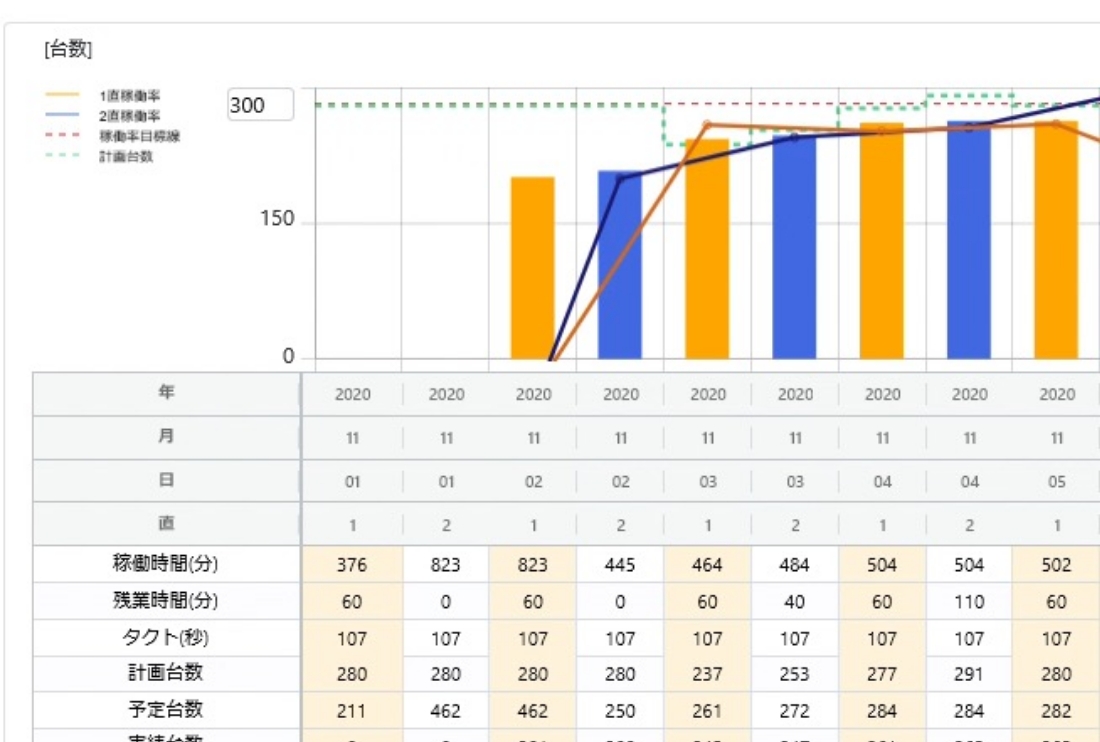

Trend analysis function

(graphing and file output)

Accumulated big data can be extracted under any conditions and facilitating data analysis through graphing and file output.

Defective Product outflow

prevention function

Real-time information of production history from big data of centrally managed production facilities prevents outflow of defective products and ensures higher quality assurance.

Features of Each Product

A Traceability System that Guarantees Quality

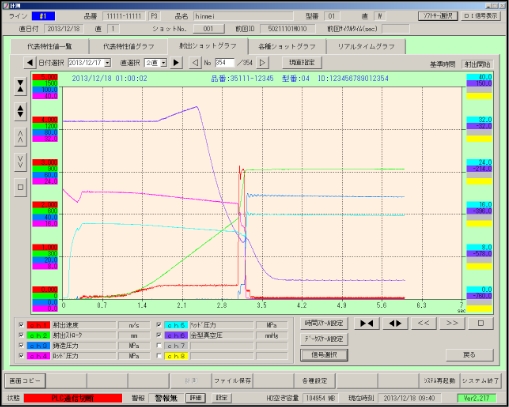

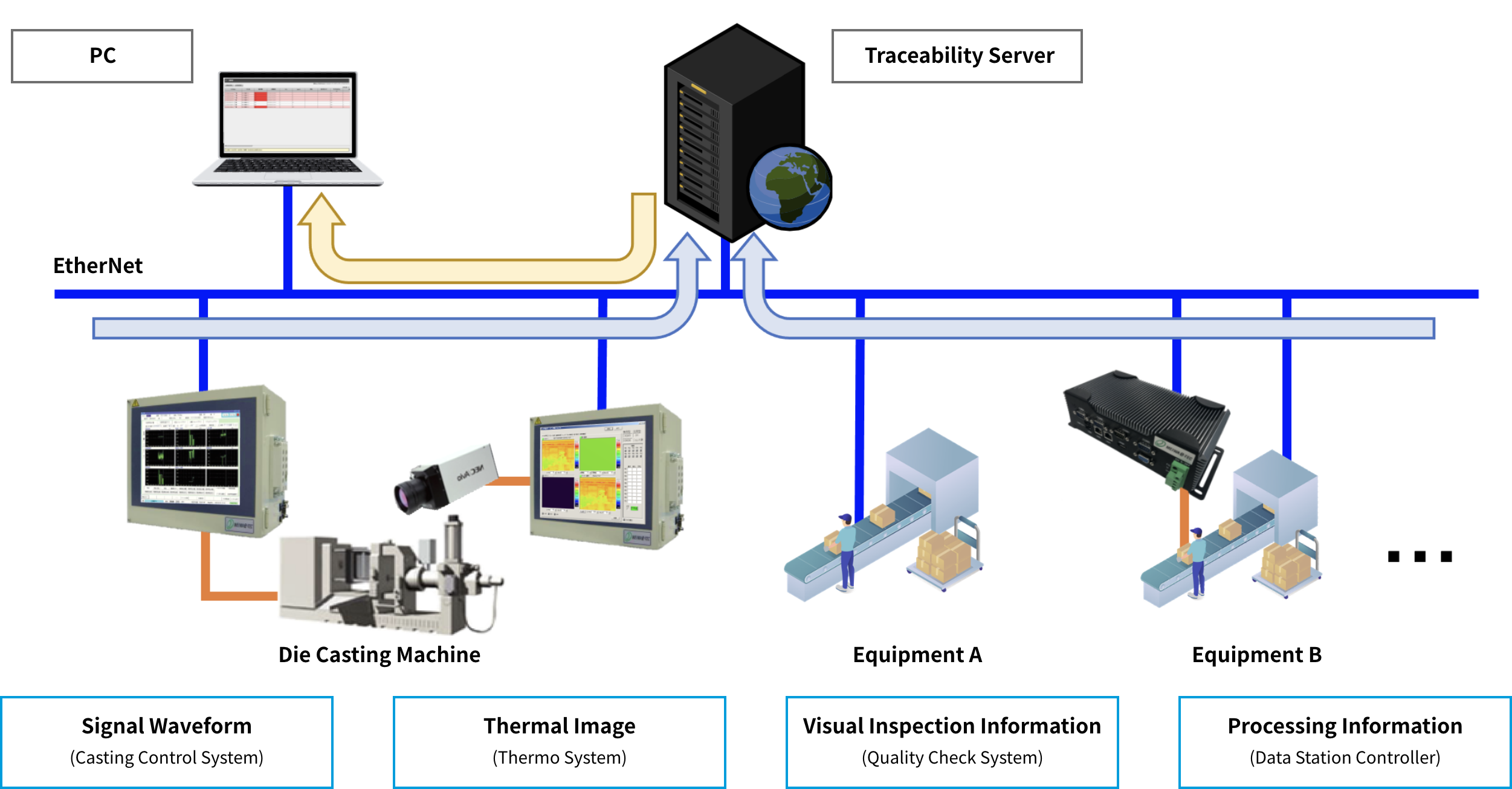

Equipment Condition Monitoring System

Casting Control Center 21

Determines passes or fails from the die cast machine by signal waveform during production.

Features

- Waveform sampling in 1ms

- Can alert as defect when the measured value is out of specification.

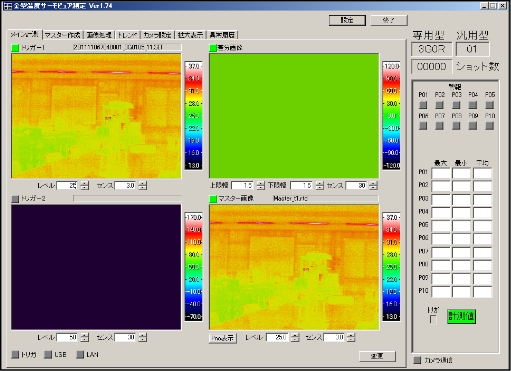

Thermal Image Management System

Thermo System

Check the die casting mold temperature during production.

Features

- Monitor and record in units of 0.1℃

- Judgement in specifying the area

- Able to judge using a master photograph taken in advance

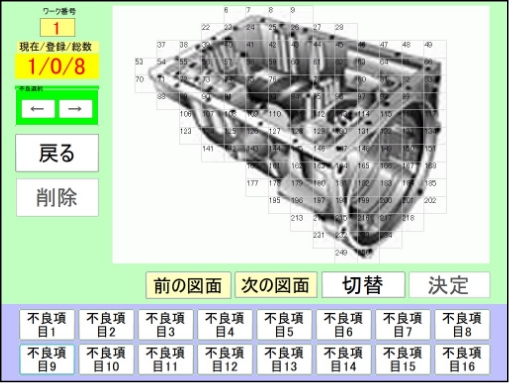

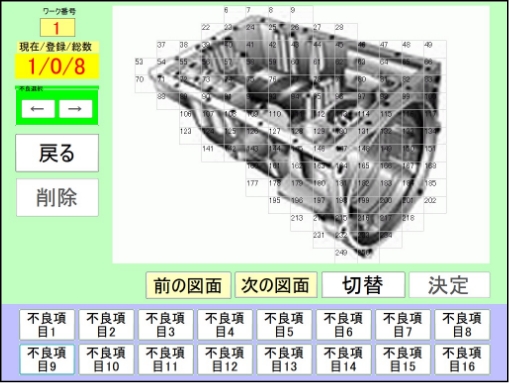

QC Data Input System

Quality Check System

Save the digitalized visual inspection

Features

- Easy operation by touch panel.

- Record not only defect area but also defect categories such as scratches and dents.

Production Data Collecting System

Data Station Controller

Installed on existing equipment to collect data

Features

- Equipped with RS232C/LAN connector/ USB, compatible with various measuring devices

- Defect is determined in cooperation with the server

System Configuration Example

The collected information is stored on a traceability server and can be viewed on a PC or other devices.

Our Services

Three functions to solve “on-site issues” from customers.

One-stop

for Service

You don’t need to be concerned about things like, “I don’t know how to generate data,” or “ I need assistance how to line up data“. From specification suggestions to facility modifications, information collecting, infrastructure development, and system installation, we provide a whole service.

Customize According

to the Information

You Want to Know

Understand our customers’ needs and offer accurate suggestions for browsing methods that match the information you want to know. We can freely customize the information and expressions being displayed.

Design Exclusively for

Production Facilities

We will investigate the production equipment and design it according to the equipment used, in addition to providing adaptable support for local communication and distinct FA equipment. We can also propose additional sensors and data collection terminals.

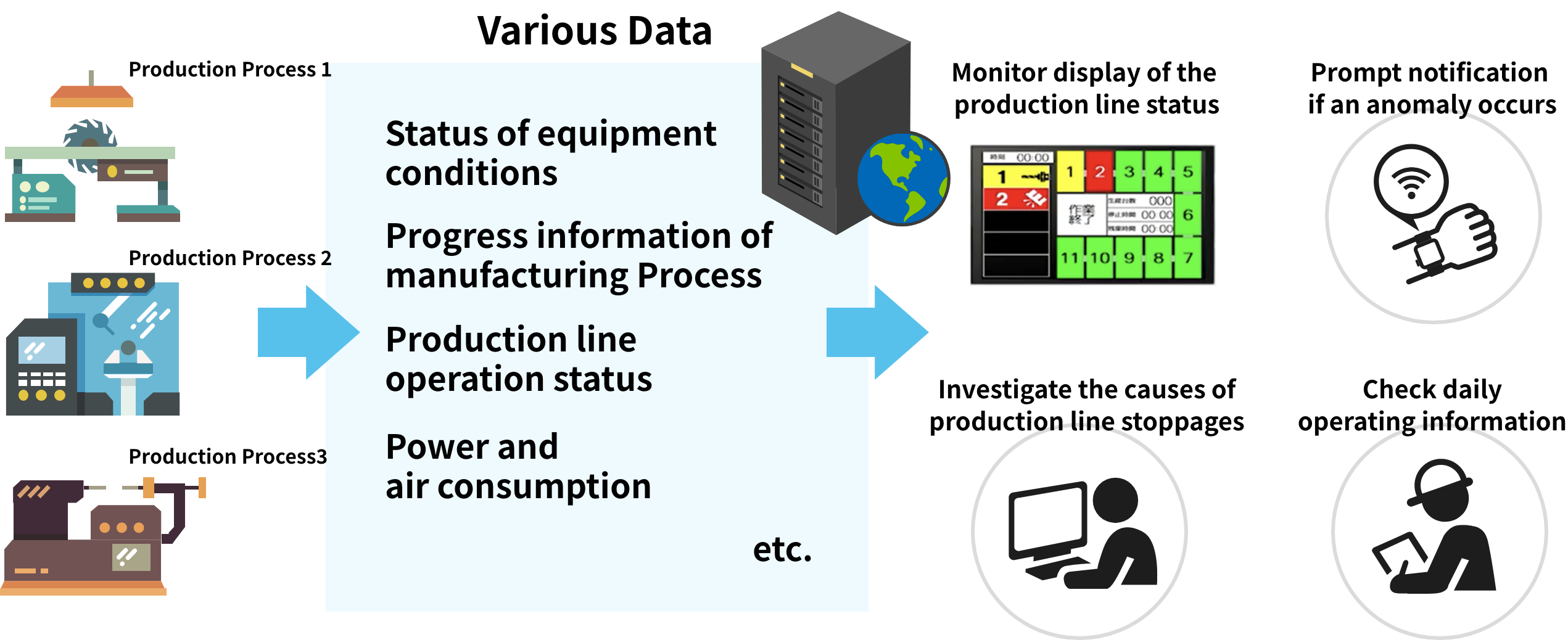

Our Advantage

Production line data will be gathered and present in a customized way, including monitoring the status of production equipment, managing operating rates, managing production progress, etc. Our ability to adapt it to your needs is one of our strengths.

Production status management image

Energy management image